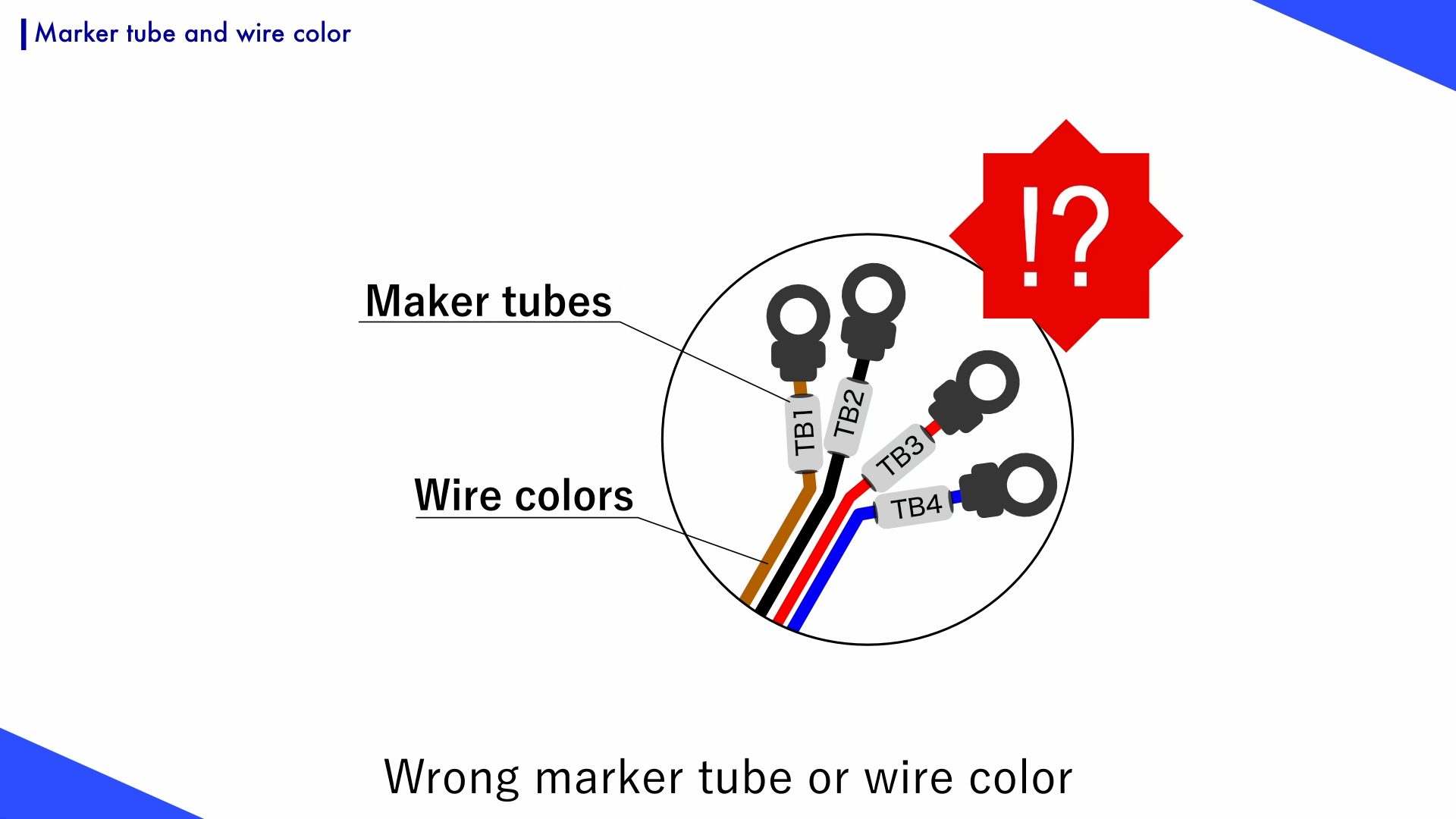

[Cable & Harness Defects] Marker tube (labeling) and wire color errors

Marker tube and wire color errors are manufacturing errors commonly found in cables and harnesses. In this video, we will show you how this error occurs and introduce an inspection to prevent outflow.

Why do "Marker tube (labeling) and wire color errors" occur?

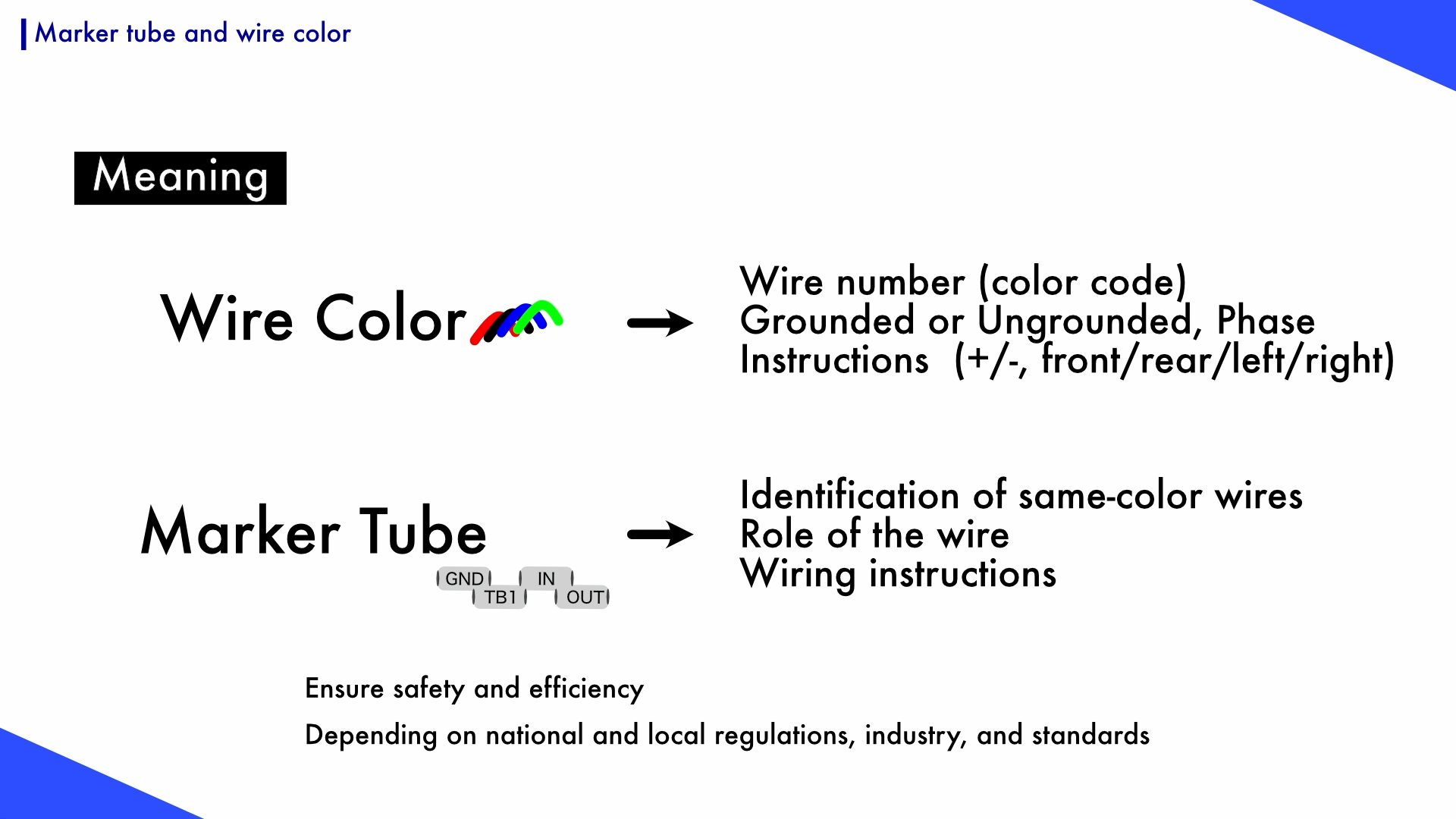

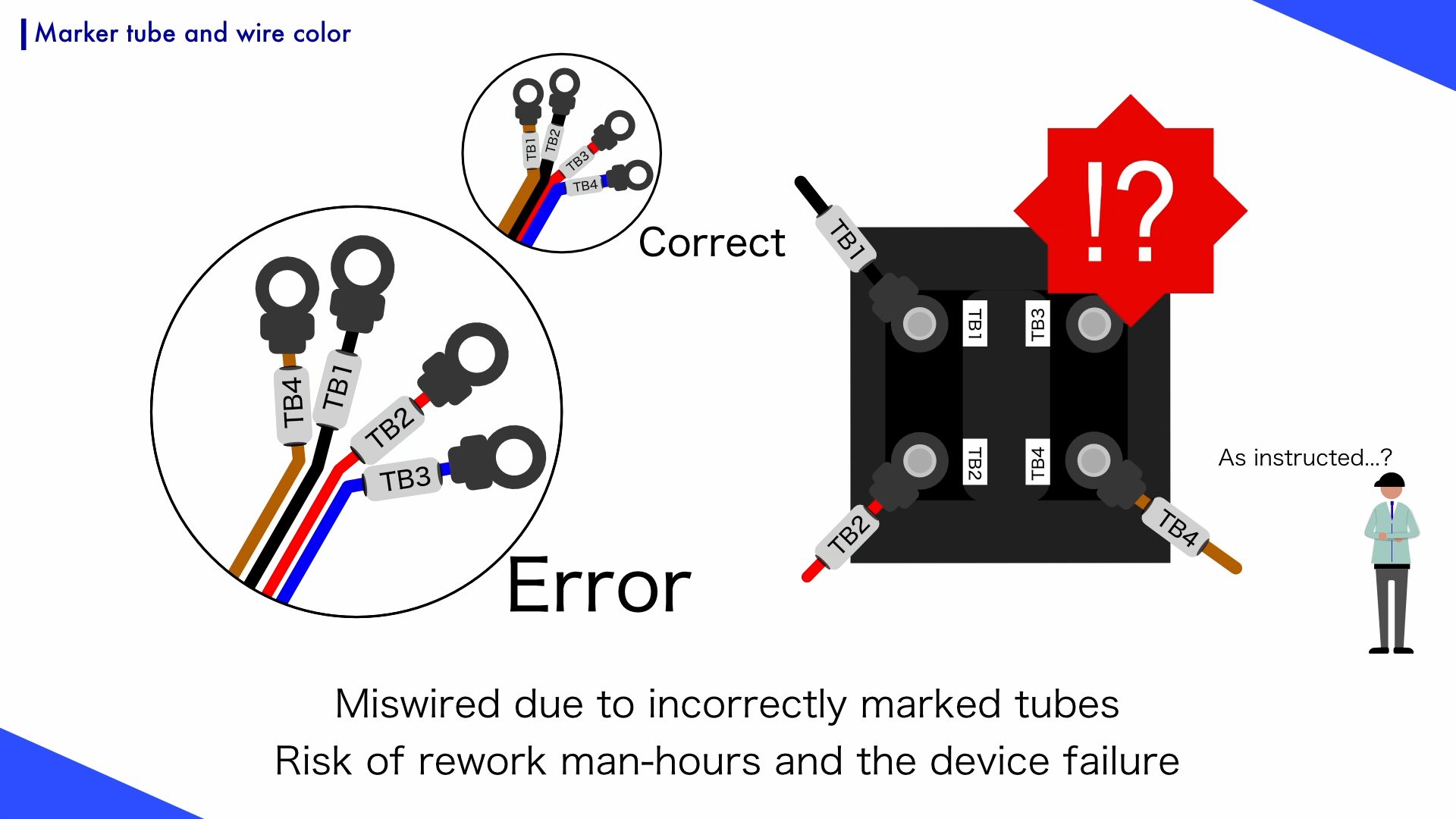

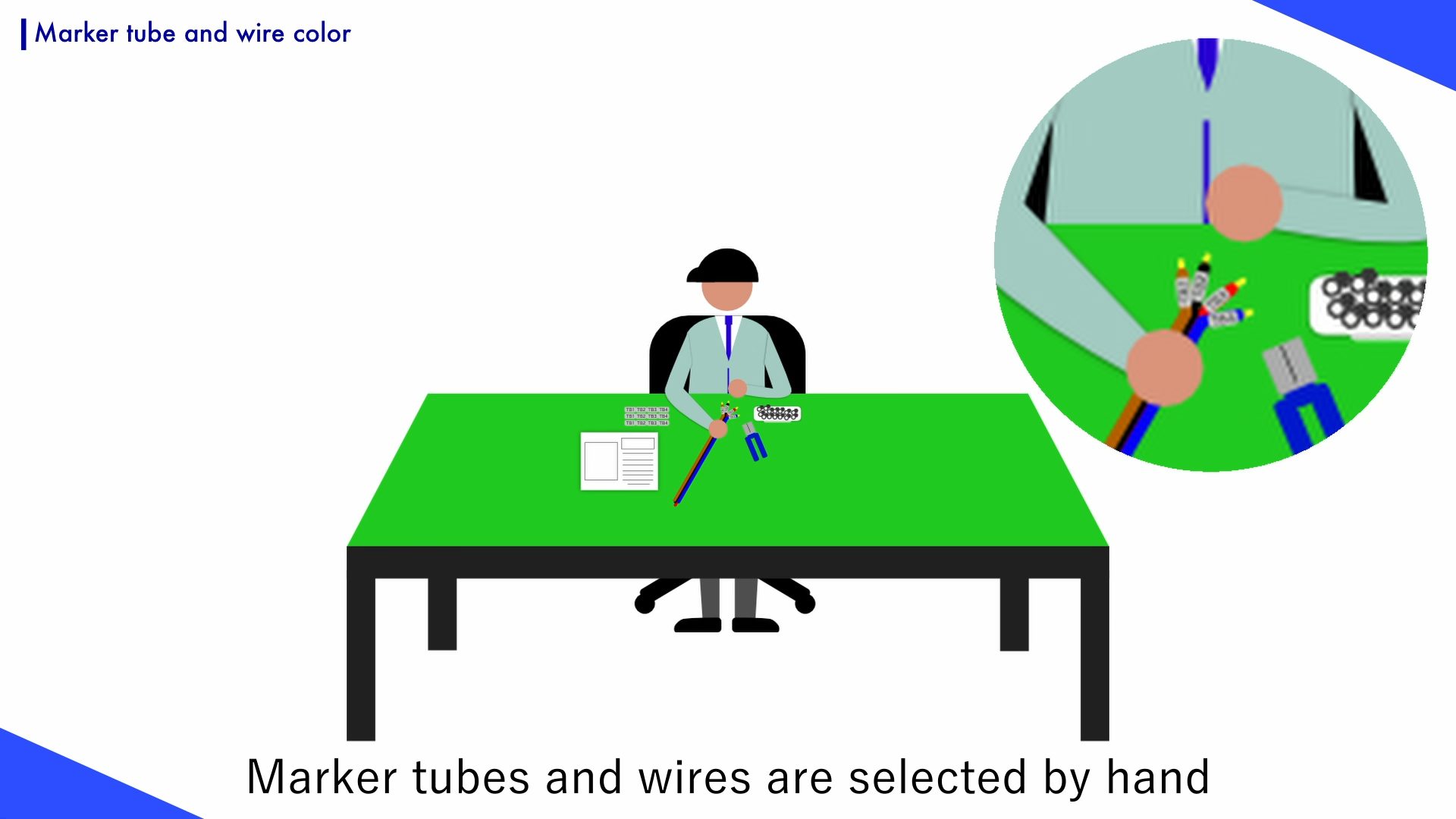

Even with the wrong marker tube or wire color, if the wiring is correct, there is no electrical error. However, marker tubes and wire colors have meaning. They are important information that helps in wiring work and confirmation in later processes. If these are incorrect, it will trigger work errors and lead to misconnection to the device. As a result, it can cause a serious accident and is very dangerous. Since marker tubes and wires are selected by hand, mistakes can occur. What is the test to prevent this error? One of the methods is the color Inspection system. However, there are issues such as the labor required to build the environment, the difficulty of adjusting illumination levels, and the preparation of a huge number of samples. There is also the possibility of misjudging complicated targets.

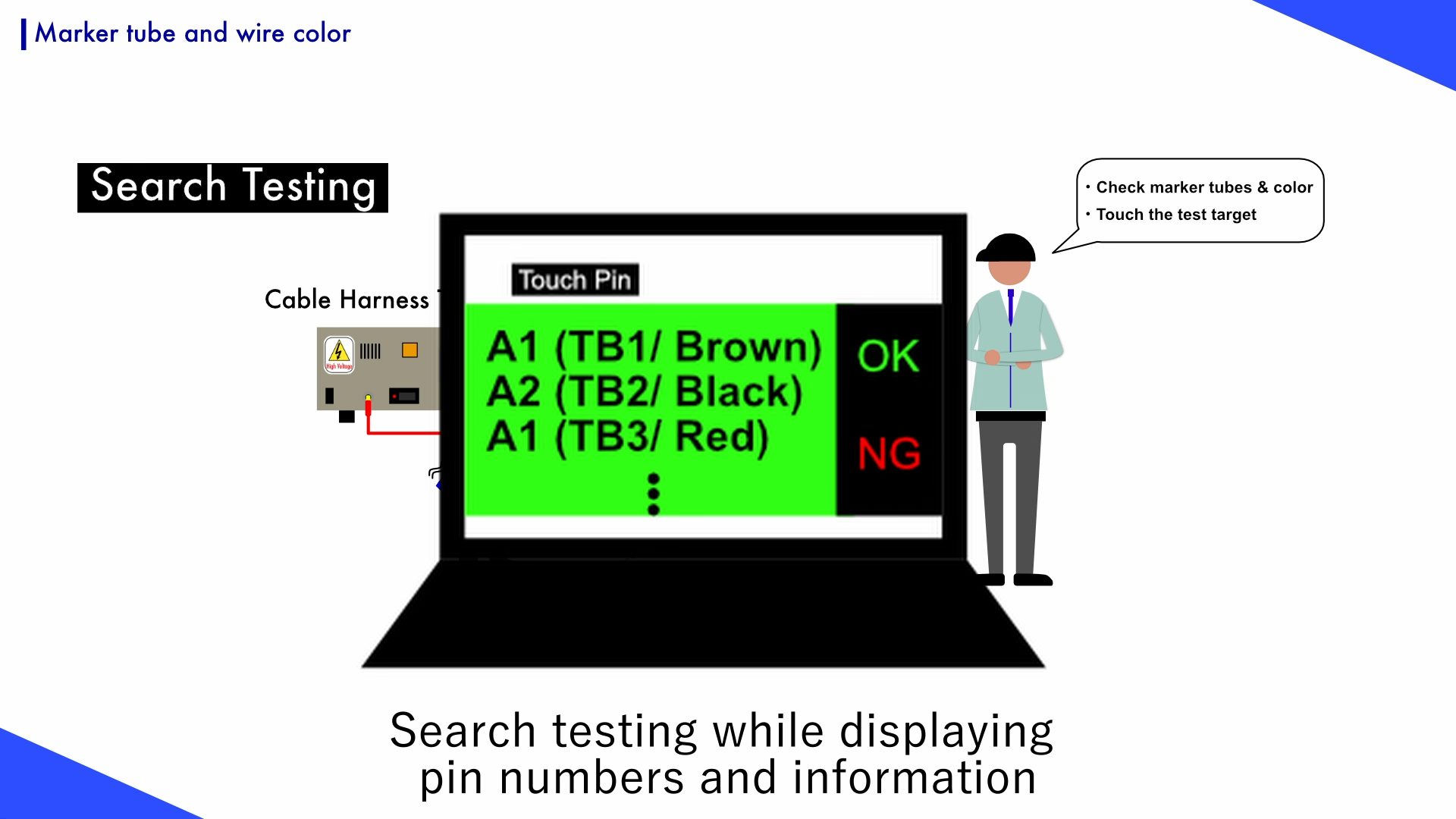

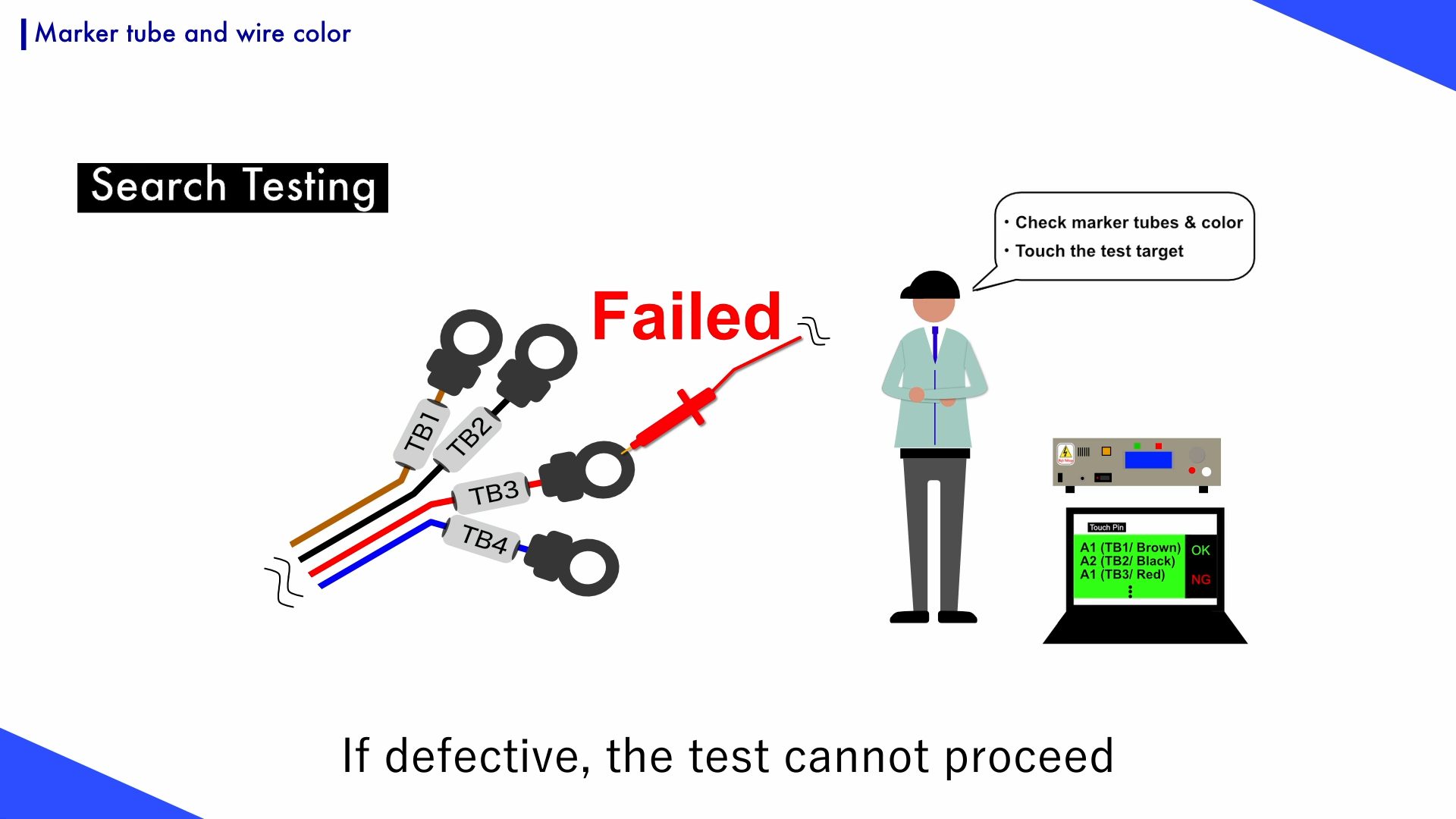

Application of Cable Harness Testing

Harness testers perform electrical checks. These cannot identify colors or characters. However, it can be used as an assistant for visual inspection. In the search testing, information on marker tubes and wire colors can be displayed. Touch and check continuity as instructed to prevent errors. If there is any error, the search testing cannot be completed. Please correct the test target. The manufacturing of wiring harnesses is still largely a manual process due to its complexity. Search testing is a standard feature of most nacman cable harness testers. Please contact us about cable harness testers to prevent marker tube and wire color errors outflow.

- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products