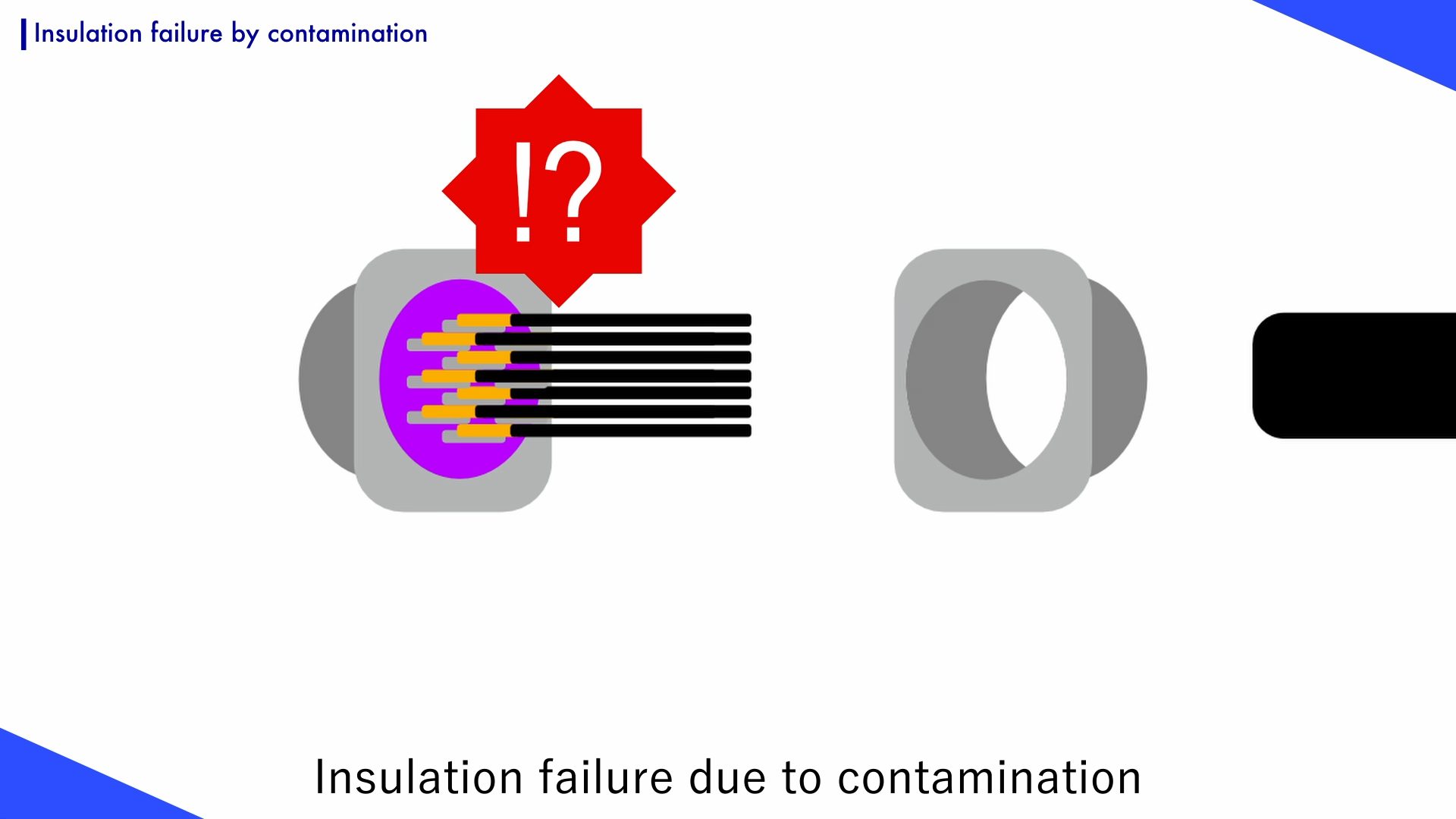

[Cable & Harness Defects] Insulation failure by contamination

Insulation failure by contamination is a manufacturing error commonly found in cables and harnesses. In this video, we will show you how this error occurs and introduce an inspection to prevent outflow.

Why does "Insulation failure by contamination" occur?

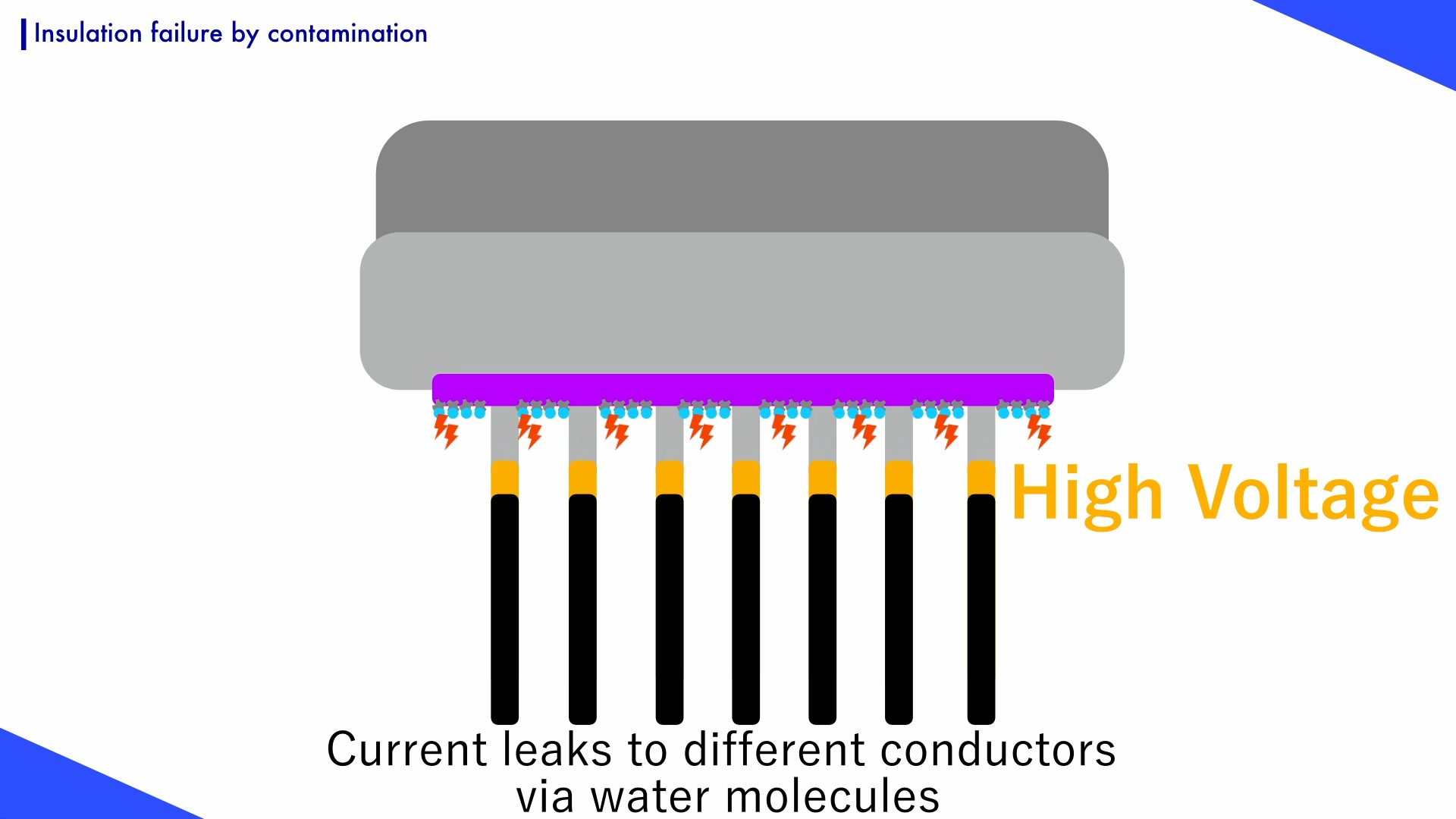

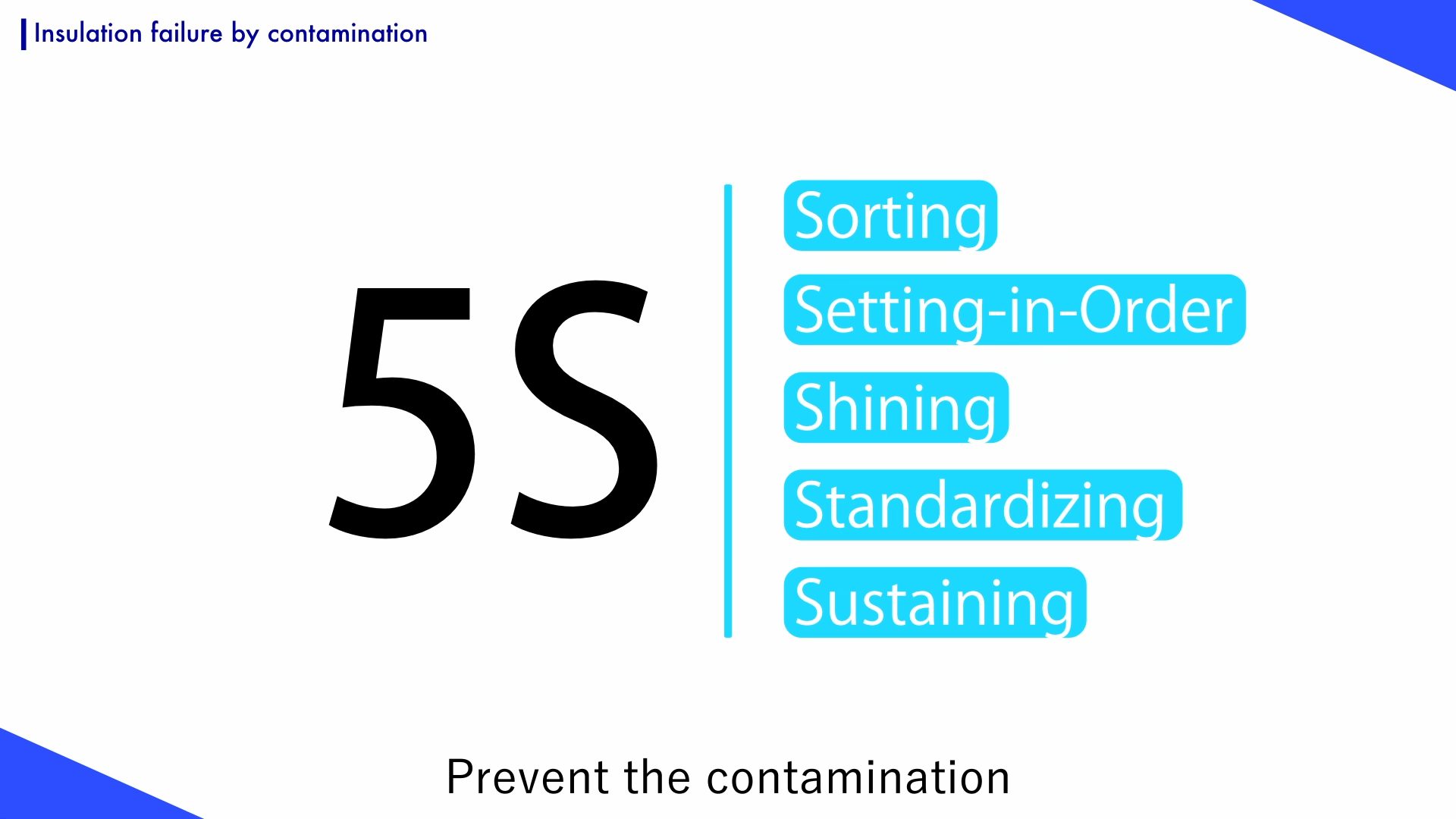

Contamination inside the connector causes insulation failure. Why does contamination cause insulation failure? When contaminants such as dust stick to the inside of a connector, they absorb moisture. Moisture absorbed by the contaminant makes it conduct electricity easily. If high voltage is applied in this state, current will leak between the different conductors, resulting in insulation failure. To prevent the outflow of contamination, it is first necessary to thoroughly implement the 5S and prevent the occurrence of defects. Even small, invisible contaminants can cause major problems if they get mixed in.

Detection by electrical cable harness testing

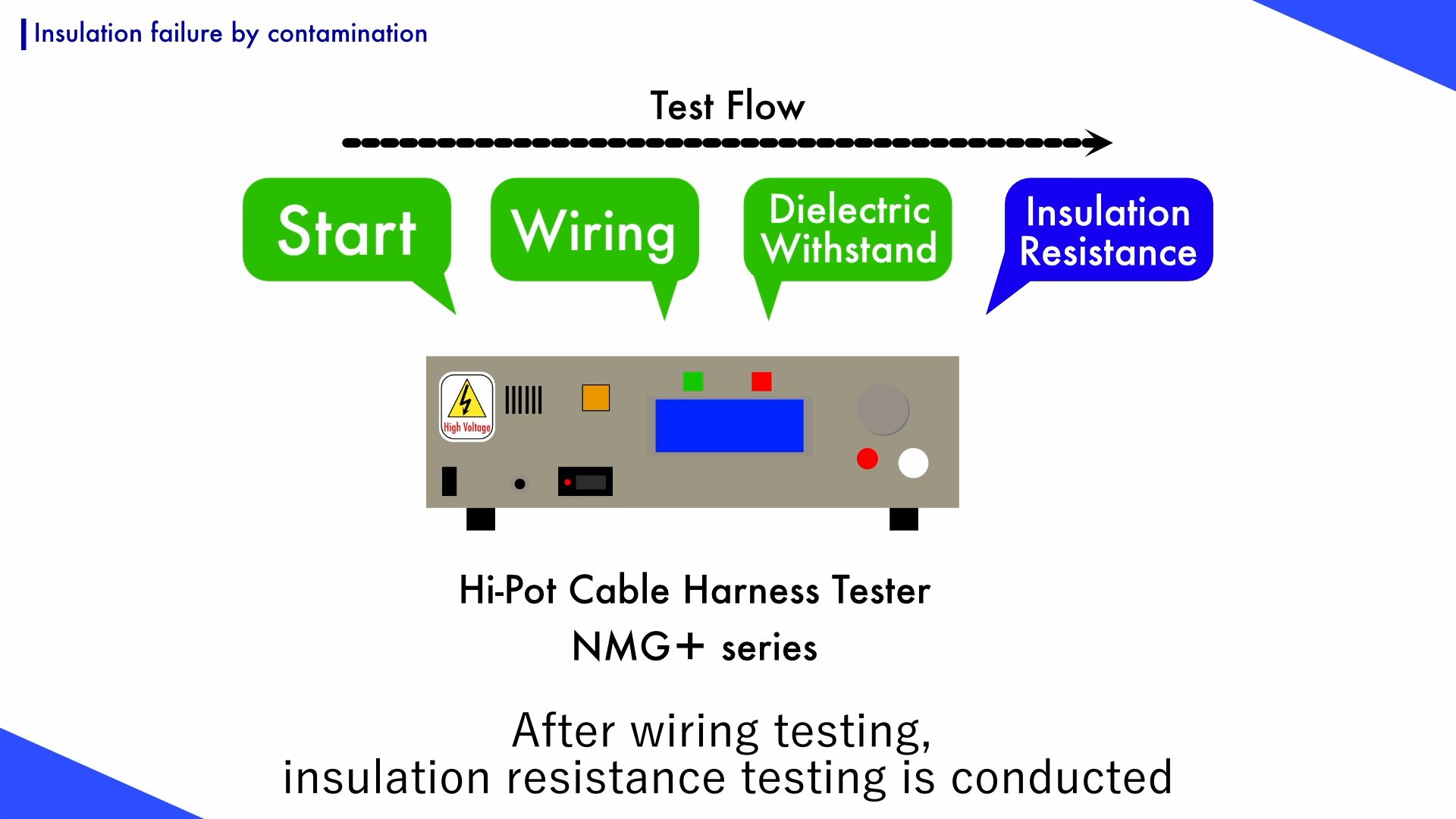

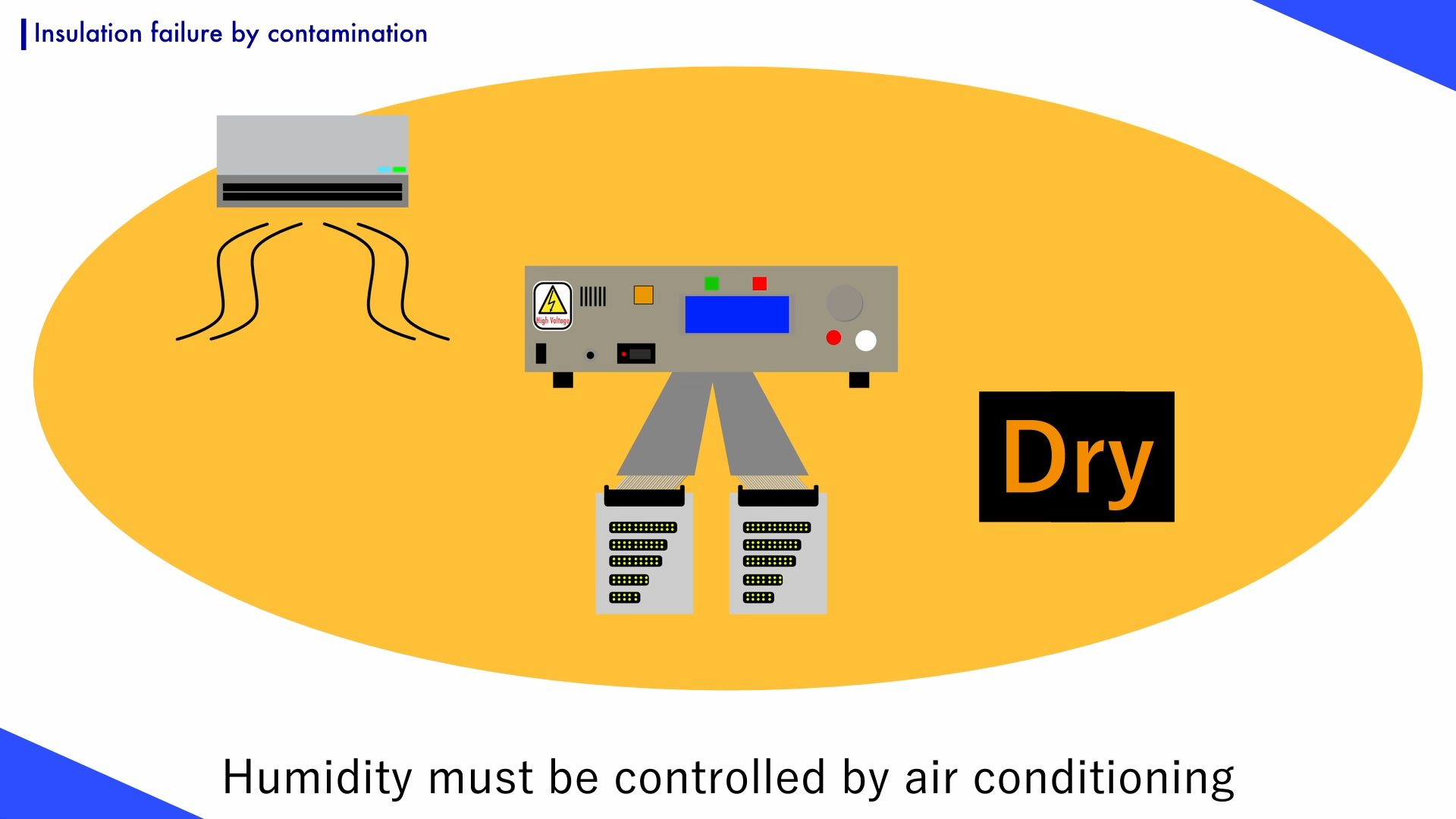

What is the inspection to prevent outflow? Image inspection is not easy to introduce due to cost and tact time. Insulation resistance testing is effective in preventing defective outflow. Harness testers can be implemented in a series of wiring and dielectric withstand voltage tests, so the introduction is smooth. Apply DC and measure the insulation resistance between different conductors. If it is less than the set judgment value, it will fail the test. If an error occurs, remove the foreign matter by an air duster. Insulation resistance testing is related to humidity. By conducting insulation resistance testing under dry conditions, the true insulation resistance value can be measured. If the test cannot be performed correctly due to high humidity, the testing facility should be left in a dry environment to remove the humidity. Please contact us about cable harness testers for detecting Insulation failure by contamination.

- Product Search

- Inspection Spec

- Category

- Options

- Discontinued Product

- All Products